When electrical devices are worked on in an energized state, there is potential for worker exposure to electrical arc-flash or arc-blast. Workers may also be exposed to arc flash hazards when performing day to day switching operations on high energy devices. The effects of these hazards range from mild sensations, to injury, to death, and property damage.

An arc flash (also known as arc blast) is a sudden, explosive electrical arc that results from a short circuit through air. An electrical arc flash can reach temperatures in excess of 20,000 degrees Celsius in no more than 1/1000 of a second, becoming an electrically-conductive plasma. The sudden heating can cause a shock wave blast equivalent to several sticks of dynamite and carrying vaporized metal and shrapnel. At temperatures over 2567 C., copper vaporizes and expands to over 67,000 times its normal volume in its solid state. The explosion created by this rapid vaporization may injure workers through exposure to heat, pressure waves, noise, light (including ultraviolet and infrared wavelengths), toxic vapours, projectiles or other means.

An arc flash is not just an electrical arc. Arc flash is perhaps the most dangerous hazard facing electrical workers. It does not require contact with a live conductor, and can cause severe injury or death.

What Causes Arc Flash?

An arc flash occurs when a conducting object approaches an exposed, high-amp electrical source. High voltage is not required for an arc flash. Most incidents occur on 120 to 240V equipment, and arc flashes can occur at voltages as low as 50V. Arc flash is a danger whenever energized equipment is being worked on, but there are certain conditions that make arc flash more likely. These conditions include:

•Dropped tools or other sources of sparks near energized equipment

•Gaps in insulating materials which expose conducting surfaces

•Corroded or improperly installed or maintained equipment

Arc flash most often occurs when performing the following tasks:

•Removing panels and opening electrical equipment doors

•Racking breakers

•Opening and closing breakers

•Taking voltage measurements

How Common Is Arc Flash?

In the United States, between 5 and 10 arc flash incidents causing severe injury occur every day. One or two result in death. In addition, there is an unknown number of arc flashes resulting in more minor injuries and damage to equipment. Although arc flash incidents are less common than electric shocks, more than 50% of burn-center admittances for electrical injuries are from arc flash.

What Are the Effects of Arc Flash?

The temperatures associated with arc flash can exceed the surface temperature of the sun. The accompanying shock wave may be capable of propelling shrapnel at speeds up to 700 mph. The worker closest to the blast is not the only one in danger. Many of the effects of arc flash, including flying metal and burns, may affect bystanders at some distance from the blast. Death is a very real possibility, but even if a worker survives the blast, they may be left with serious injuries, including:

•Burns from direct heat exposure or clothing ignition. Arc flash is capable of causing serious burns requiring skin grafts at distances of more than 10 feet.

•Hearing damage or total hearing loss from ruptured eardrums. The sound of a blast can exceed 160 dB (Sounds above 140 dB cause hearing loss even with protective equipment.)

•Loss of eyesight from UV light emitted by vaporized metal

•Lung collapse or scarring from the shock wave and inhalation of vaporized metal

•Memory loss and other neurological damage from concussion

•Injuries from flying shrapnel

•Injuries from falls or collision with equipment. An arc fault of 50 kA can accelerate a nearby worker at speeds of up to 110 mph.

Definitions:

Arc Thermal Protective Value (ATPV): The incident energy in Calories/squared cm on a fabric that results in a 50% probability of the onset of second degree burn based on the Stoll Curve.

Circuit Breaker/Fuse: A device designed to open and close a circuit by not-automatic means and to open the circuit automatically on a predetermined over current without damage to itself when properly applied within its rating.

Cal/cm2 (Calories per square centimeter): The total energy on a surface area used for arc ratings.

Dead Front: No live parts exposed to a person on the operating side of the equipment.

De-energized: Free from any electrical connection to a source of potential difference and from electrical charge not having a potential different from that of the earth.

Electrical Hazard: A dangerous condition such that contact with electrical equipment or equipment failure can result in electric shock, arc flash burn, thermal burn, or blast.

Electrically Safe Work Condition: A state whereby electrical equipment or systems, whether previously energized or not, are determined to be safe by ensuring all sources of energy are isolated and all potential charges are removed. This state may also require the addition of grounding devices to prevent the system from being energized even if a source of energy is inadvertently connected.

Energized: Electrically connected to or having a source of voltage.

Flash Hazard: A dangerous condition associated with the release of energy caused by an electric arc.

Flash Hazard Analysis: Is a study investigating a worker’s potential exposure to arc flash energy, conducted for the purpose of injury prevention and the determination of safe work practices and appropriate levels of PPE.

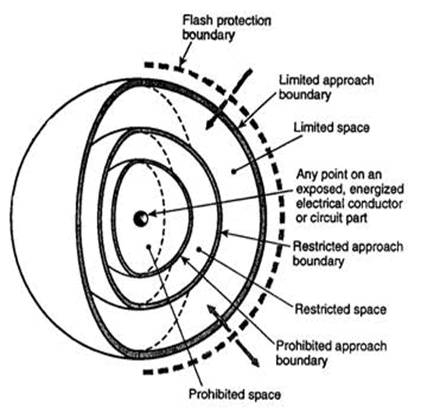

Flash Protection Boundary: An approach limit from exposed live parts in which a person could receive a second degree burn if an electrical arc flash were to occur. No special consideration for PPE is required outside of this boundary.

Incident Energy: The amount of energy at the working distance due to an arc flash; expressed in cal/cm2 or J/cm2.

Limited Approach Boundary: An approach limit which is the distance from an exposed live part within which a shock hazard exists.

Prohibited Approach Boundary: An approach limit distance from an exposed live part within which work is considered the same as making contact with the live part.

Restricted Approach Boundary: An approach limit distance from an exposed live part within which there is an increased risk of shock, due to electrical arc-over combined with inadvertent movement, for personnel working in close proximity to the live part.

Working Distance: The minimum distance the face and torso of a worker should be away from a possible arc point.

Qualified Worker: In relation to an employee, a person who has been trained and instructed in the tasks they are responsible for and authorized to perform those duties first by adequate demonstration of competency and by job description or supervisor authority. For the appropriate legislated definitions, refer to the Sask. OH&S Acts and Regulations.

Qualified Electrical Worker: A person who is trained and knowledgeable regarding working within electrical systems and trained in electrical safety and awareness. This worker will have achieved a degree, certificate, or diploma recognized by operating authorities as acceptable for doing electrical work.

V-Rated Gloves: Are gloves rated and tested for the maximum line-to-line voltage upon which work will be performed.

V-Rated Tools: Are tools rated and tested for the maximum line-to-line voltage upon which work will be performed.

Electrical Safety Principles

All jobs must be planned, including a step by step procedure for completion of the job. Discuss hazards and procedures in a pre-job safety meeting with your supervisor and co-workers before starting the job. If you are unsure of a procedure, job plan, or you feel the workplace is unsafe, stop work and confirm with your supervisor. The following steps must be used prior to starting any job:

•Identify the hazards; do a pre-job hazard analysis and complete the pre-job safety meeting form and discuss with all workers on site.

•Create a work plan that will safely complete the task to be performed as per the requirements of the arc flash program. Items to be discussed should include but not be limited to PPE required, safety watch required, and designated safe work area.

•Complete a safe work permit with the contracting company if applicable.

•Ensure the arc flash portion of the contractor JHA for all category 2 and 2* live electrical work is completed.

•If required, get a Hot Work or live electrical work permit from the contractor (category 4 only)

•Minimize the hazards. De-energize the equipment or insulate or isolate exposed live parts so you cannot contact them. If this is not possible, use the proper PPE and tools to match the hazard.

•Anticipate problems. If it can go wrong it might. Make sure you have the right PPE and tools for the worst case scenario.

•Only qualified, trained personnel may perform electrical work.

Personal Protective Equipment (PPE)

PPE referenced in this document is specific to electrical safety, and the equipment used in ensuring the safety of the worker before and during any electrical activity is performed.

The following list is typical PPE used in electrical safety that may require regular maintenance, testing, or care. Other safety equipment that is not listed, but that provides personal safety, and requires maintenance should also be considered as part of this list:

1.Arc flash resistant coveralls

2.Arc flash suit (“bomb suit”)

3.Arc flash face shield

4.Rubber gloves (V rated)

5.Leather gloves (rubber glove cover)

6.Hot sticks (V rated)

7.Ground chains (clamps or clusters)

8.Voltage testers

9.Multi-meters

10.CSA work boots

11.Hard hats

12.Safety glasses

13.Hearing protection

Selection of Appropriate Arc Flash PPE

Appropriate arc flash PPE is determined by the arc flash hazard level. The following must be taken into consideration when selecting proper PPE:

•The PPE category must be selected based on the incident heat energy within the working distance for the task to be performed.

•The protective clothing must be chosen so the clothing rating in cal/cm2 is greater than the calculated incident energy.

•PPE must cover the entire body when working within the arc flash boundary to provide protection from receiving second degree burns. This may include, but is not limited to, arc flash suit with face shield, safety glasses, non-conductive head protection, and leather gloves and footwear. Rubber insulating gloves shall be worn for protection from electric shock due to inadvertent contact with an energized electrical conductor or circuit parts.

If arc flash hazard levels exceed 40 cal/cm2, energized work shall not be performed directly even with the application of PPE with an ATPV higher than 40 cal/cm2. Other methods to perform the work required must be evaluated and a JHA performed. Suggestions for performing work on equipment with AFHL higher than category 4 include:

•De-energize (whenever possible)

•Remote racking devices or remote operators

•Blast walls or obstructions to prevent exposure

•Reducing over current settings through relay-setting modification or maintenance switches

•Implementation of light sensing or other fast-acting disconnection methods

•Implementation of current limiting fuses or other short-circuit limiting devices (quenchers)

Minimum Standard For PPE:

•When working on or around live circuits, never wear clothing made from synthetic materials such as acetate, nylon, polyester, or rayon – alone or combined with cotton. Such clothing is dangerous as it can burn and melt into your skin.

•The type of PPE depends on the type of electric work being attempted. Once the hazard risk category is identified, suit up to the proper PPE before working on or near energized equipment within the flash protection boundary. PPE will protect against electric shock and incurable arc flash burns, but may not protect you against physical injuries from an arc blast.

•When working on energized equipment, all electrically conductive jewelery must be removed (e.g., chains, rings, and body piercing products).

Inspection And Maintenance Of Arc Flash PPE

Maintenance and care for arc flash and voltage rated PPE is essential to its performance and reliability. In this regard, the following responsibilities are outlined:

•The user of the energized equipment PPE is responsible for the inspection, care, and proper use of all items in accordance with the manufacturers specifications and regulatory requirements (OHS, CSA, etc.).

•Storage of the equipment should be in a protective pouch or bag.

•Equipment must be kept clean at all times.

•Face shields must be inspected for cracks or scratches that may impede its purpose or use, or impede visibility.

•Hard hat and face shield must be used as one complete assembly.

•Gloves must be inspected prior to use for nicks, cuts, scuffs, and low pressure tested to eliminate the possibility of pinholes. If gloves fail to meet any of the criteria listed above, they must be discarded.

•Rubber gloves should be used with the leather protector at all times to ensure the rubber glove is protected from damage and there is arc flash protection for the hands.

•Rubber gloves must be tested as per the manufacturers specifications.

•Leather gloves provide arc flash protection only.

•Protective FR clothing must have a rating in cal/cm2 that is greater than the calculated incident energy. Minimum 8 Cal/cm2. Clothing must be free of rips and tears.

The following table is the minimum standard for PPE when working on energized circuits.

Select the Hazard/Risk Category by using the charts on the following pages.

Hazard/Risk Category PPE and Tool Requirements |

Category 0 & 1: •Standard fire-retardant coveralls •Safety goggles or an arc-rated face shield •Leather or insulated gloves •Insulated tools |

Category 2: •Minimum 8 cal/cm2 rated coveralls •Arc-rated face shield •Hearing protection •Voltage rated gloves and insulated tools |

Category 2*: •Minimum 8 cal/cm2 rated coveralls •Arc-rated face shield •Hearing protection •Balaclava for head and neck protection is required •Voltage rated gloves and insulated tools |

Category 3 & 4: •Minimum 40 cal/cm2 rated flash suit •Flash suit hood •Hearing protection •Voltage rated gloves and insulated tools |

Hazard/Risk Categories Classifications And Use Of PPE:

After selecting the Hazard/Risk Category from the charts below, select the required PPE by using the chart on the previous page.

Taking readings on HV splitters of ESP’s are a risk category 2 with appropriate voltage rated gloves.

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

600 V class motor control centres (MCC) (except as indicated) |

|||

Work on control circuits with exposed energized electrical conductors and circuit parts 120V or below, exposed |

0 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts greater than 120V, exposed |

2* |

Y |

Y |

Insertion or removal of individual starter “buckets” from MCC |

4 |

Y |

N |

Application of safety grounds after voltage test |

2* |

Y |

N |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

4 |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

1 |

N |

N |

Work on exposed energized electrical conductors and circuit parts of utilization equipment fed directly by a branch circuit of the panel board or switchboard |

2* |

Y |

Y |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

600 V class switchgear (with power circuit breakers or fused switches) |

|||

Perform infrared thermography and other non-contact inspections outside the restricted approach boundary |

2 |

N |

N |

CB or fused-switch operation with enclosure doors closed |

0 |

N |

N |

Reading a panel meter while operating a meter switch |

0 |

N |

N |

CB or fused-switch operation with enclosure doors open |

1 |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

2* |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts 120V or below, exposed |

0 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts greater than 120V, exposed |

2* |

Y |

Y |

Insertion or removal (racking) of CBs from cubicles, doors open or closed |

4 |

N |

N |

Application of safety grounds after voltage test |

2* |

Y |

N |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

4 |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

2 |

N |

N |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

Other 600V class (277 to 600V, nominal) equipment |

|||

Lighting or small power transformers (600V maximum) |

-- |

-- |

-- |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

2* |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

1 |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

2* |

Y |

Y |

Application of safety grounds after voltage test |

2* |

Y |

N |

Revenue meters (kW-h at primary voltage and current) – insertion or removal |

2* |

Y |

N |

Cable trough or tray cover removal or installation |

1 |

N |

N |

Miscellaneous equipment cover removal or installation |

1 |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

2* |

Y |

Y |

Application of safety grounds after voltage test |

2* |

Y |

N |

Insertion of or removal of plug-in devices into or from busways |

2* |

N |

N |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

NEMA E2 (fused contactor) motor starters, 2.3 to 7.2 kV |

|||

Perform infrared thermography and other non-contact inspections outside the restricted approach boundary |

3 |

N |

N |

Contactor operation with enclosure doors closed |

0 |

N |

N |

Reading a panel meter while operating a meter switch |

0 |

N |

N |

Contactor operation with enclosure doors open |

2* |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

4 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts 120V or below, exposed |

0 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts greater than 120V, exposed |

3 |

Y |

Y |

Insertion or removal (racking) of starters from cubicles, doors open or closed |

4 |

N |

N |

Application of safety grounds after voltage test |

3 |

Y |

N |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

4 |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

3 |

N |

N |

Insertion or removal (racking) of starters from cubicles of arc-resistant construction, tested in accordance with IEEE C37.20.7, doors closed only |

0 |

N |

N |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

Metal-clad switchgear, 1 to 38kV |

|||

Perform infrared thermography and other non-contact inspections outside the restricted approach boundary |

3 |

N |

N |

CB operation with enclosure doors closed |

2 |

N |

N |

Reading a panel meter while operating a meter switch |

0 |

N |

N |

CB operation with enclosure doors open |

4 |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

4 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts 120V or below, exposed |

2 |

Y |

Y |

Work on control circuits with exposed energized electrical conductors and circuit parts greater than 120V, exposed |

4 |

Y |

Y |

Insertion or removal (racking) of CBs from cubicles, doors open or closed |

4 |

N |

N |

Application of safety grounds after voltage test |

4 |

Y |

N |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

4 |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

3 |

N |

N |

Opening of voltage transformer or control power transformer compartments |

4 |

N |

N |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

Arc-resistant switchgear Type 1 or 2 (for clearing times of less than 0.5 s, with protective fault current not to exceed the arc-resistant rating of the equipment) |

|||

CB operation with enclosure doors closed |

0 |

N |

N |

Insertion or removal (racking) of CBs from cubicles, doors closed |

0 |

N |

N |

Insertion or removal (racking) of CBs from cubicles, doors open |

4 |

N |

N |

Work on control circuits with exposed energized electrical conductors and circuit parts 120V or below, exposed |

2 |

Y |

Y |

Insertion or removal (racking) of ground and test device with door closed |

0 |

N |

N |

Insertion or removal (racking) of voltage transformers on or off the bus, door closed |

0 |

N |

N |

Task(s) performed on energized equipment: |

Hazard/Risk Category |

Rubber Insulating Gloves Required? |

Insulated and Insulating Hand Tools Required? |

Other equipment 1 to 38 kV |

|||

Metal-enclosed interrupter switchgear, fused or unfused |

-- |

-- |

-- |

Switch operation of arc-resistant type construction, tested in accordance with IEEE C37.20.7, doors closed only |

0 |

N |

N |

Switch operation, doors closed |

2 |

N |

N |

Work on exposed energized electrical conductors and circuit parts, including voltage testing |

4 |

Y |

Y |

Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) |

4 |

N |

N |

Opening of hinged covers (to expose bare energized electrical conductors and circuit parts) |

3 |

N |

N |

Outdoor disconnect switch operation (hookstick operated) |

3 |

Y |

Y |

Outdoor disconnect switch operation (gang-operated, from grade) |

2 |

Y |

N |

Insulated cable examination, in manhole or other confined space |

4 |

Y |

N |

Insulated cable examination, in open area |

2 |

Y |

N |

Arc Flash Approach Boundaries

An arc flash approach boundary is a distance from exposed live parts within which a person could receive a second degree burn if an electric arc flash were to occur.

Approach Boundaries To Energized Electrical Conductors or Circuit Parts for Shock Protection (all dimensions are distances from energized electrical conductor or circuit part to worker) |

||||

Normal System Voltage Range, Phase to Phase |

Limited Approach Boundary – Exposed Movable Conductor |

Limited Approach Boundary – Exposed Fixed Circuit Part |

Restricted Approach Boundary – Includes Inadvertent Movement Adder |

Prohibited Approach Boundary |

Less than 50 |

Not Specified |

Not Specified |

Not Specified |

Not Specified |

50 to 300 |

3.05 m (10 ft. 0 in.) |

1.07 m (3 ft. 6 in.) |

Avoid Contact |

Avoid Contact |

301 to 750 |

3.05 m (10 ft. 0 in.) |

1.07 m (3 ft. 6 in.) |

304.8mm (1 ft. 0 in.) |

25.4mm (0 ft. 1 in.) |

751 to 15 kV |

3.05 m (10 ft. 0 in.) |

1.53 m (5 ft. 0 in.) |

660.4mm (2 ft. 2 in.) |

177.8mm (0 ft. 7 in.) |